Products Category

Contact Us

Tel: +86-534-5737702

Fax: +86-534-5737703

E-mail: [email protected]

Add: No.80 Changxing road, Economic Development Zone, Dezhou, Shandong, China

Skype: betterdrilling2008

WeChat: 0086-187 6406 8509

whatsapp: 0086-187 6406 8509

Products > Drilling Fluid System Equipment > Solid Control Equipment > Drilling Fluid Equipment Mud Cleaner

|

Product name : Drilling Fluid Equipment Mud Cleaner

Model No. : BT-QJZS

Quality Standard : #API & ISO

Origin : CN

Package : Plywood case / Steel Pallet

HS code : 8431431000

|

| Details: |

4-Stage Solid Control Equipment Combining Shale Shaler, Desander, Desilter, Mud Cleaner, Centrifuge

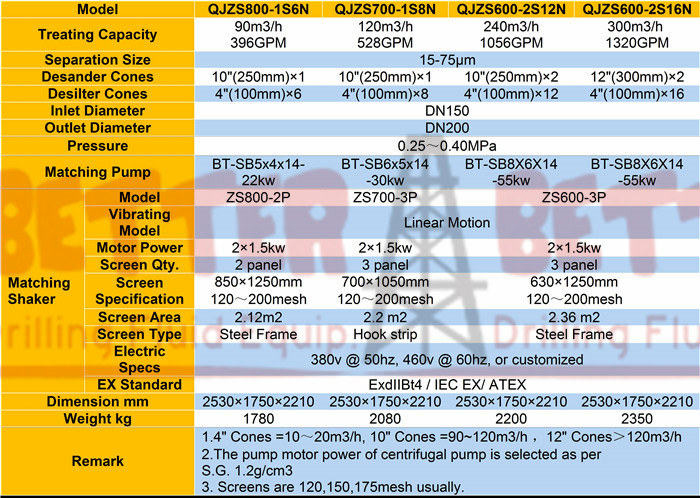

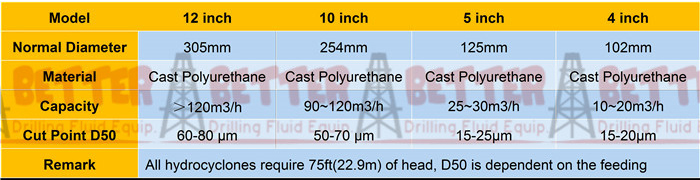

MUD CLEANER -Combined with Desander, Desilter and an Underflow shale shaker, compact design with small footprint; -Consist of a two-stage separation process using a combination of hydrocyclones mounted over a shale shaker to operation as a single unit; -Solids passed through the hydrocylones and separated particles pass through the shaker screens,and bigger particles remain on the screen and removed manually; -Desander & desilter cones made of Polyurethane ( PU ) or high-chromium cast iron or ceramic; -1-3 pcs Desander cones for optional, each cone can process 500 GPM and makes a separation between 45 and 75 μm; -8-20 pcs Desilter cones for optional, each cone can process 80 GPM, and makes a separation between 15 and 45 μm; -Effective on both oil-base and water-base weighted and unweighted drilling fluid system in removing and drying solids; -Minimizing waste generated and reducing disposal costs; -Brand electrical components of ABB, Siemens, and Schneider adopted; -Brand imported vibration motors of US Martin or Italy OLI adopted, IEC Ex, ATEX and UL Certified; Technical Parameters  HYDROCYCLONE A wide variety of hydro-cyclones for desilters and desanders as replacements for major O.E.M. brands in the 4”, 5”, 6”, 10” & 12” sizes Made of Polyurethane or abrasion-resistant alloy, Clamp design The separation of solids is dependent upon feed particle size, fluid density &viscosity, fluid feed pressure and cone apex size; Enough feeding pressure is necessary (at least 23m pressure head), less bend and T pipeline to ensure min.pressure loss. Technical Parameters  |

| Related Products : |

|

|

|

|

||||||||

|

|

|

|

Oilfield Sand/Slurry/Mud Pumps

Oilfield Sand/Slurry/Mud Pumps

Drilling Waste Management

Drilling Waste Management